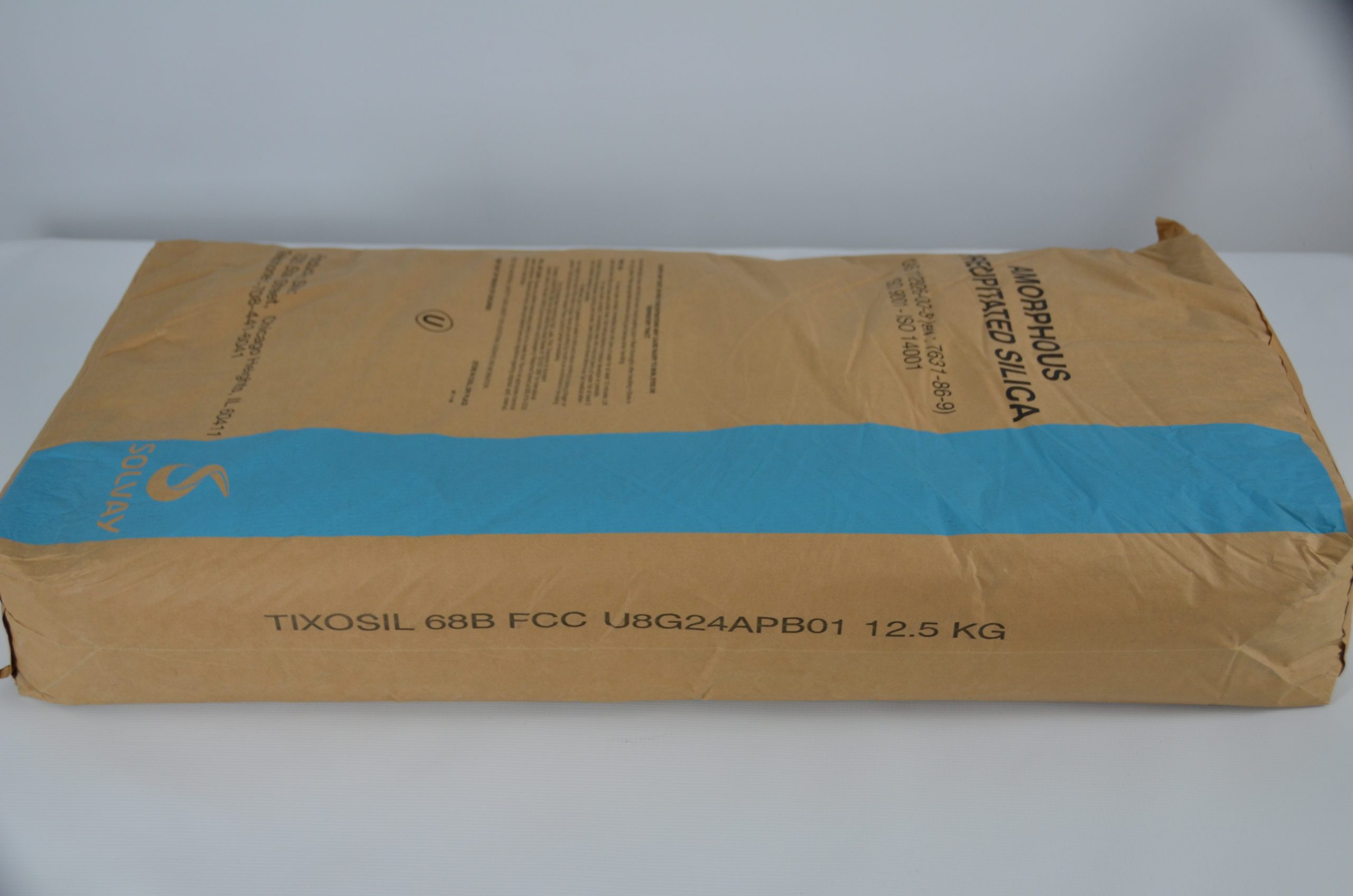

Through the implementation of this competitive rice husk ash (RHA) proprietary process in Europe, the company is able to ensure consistent product quality by leveling out variability of agro feedstocks. Tixosil is a range of synthetic precipitated amorphous silica that improves the anti-caking and freeflow properties of powders, making them easier to manipulate, transport and use.

This involves working with stakeholders across the entire value chain, and Continental is a key partner in this journey. Solvay, the worldwide innovation leader in highly dispersible silica, is the first company to commit to circular HDS production at a European site within a concrete timeframe and is now focused on building the necessary ecosystem to bring it to market. This new generation of precipitated silica will also address the needs of the home & personal care and the feed & food industries. The Group will gradually replace its existing Zeosil ® portfolio with circular HDS, providing a circular solution for tires that will contribute both to increasing the use of sustainable raw materials and reducing the tire industry’s CO 2footprint. Production is expected to start by the end of 2024. Precipitated Silicas, Sodium Aluminosilicates Website The inventor of Highly Dispersible Silica in the 90s, Solvay Silica is today a world leader with a market share of above 60 and provides innovative solutions to the challenges of sustainable mobility. This will make the Livorno site Europe’s best in class silica production site in terms of CO 2 footprint. Coupled with renewable energy integration at the plant, it will allow Solvay to achieve a 50% reduction in CO 2 per ton of silica. This new breakthrough silicate process provides a circular solution as it gives a second life to rice husk in a local value chain. Solvay is investing at its Livorno site, in Italy, to launch the company’s first unit of circular highly dispersible silica (HDS), made with bio-based sodium silicate derived from rice husk ash.

0 kommentar(er)

0 kommentar(er)